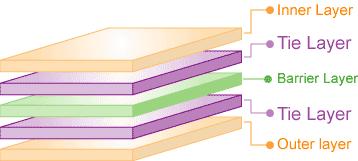

In coextruded polymer multilayers, several polymers are put in contact in the melt state in a specially designed die within the extruder. Once the multilayer has exited the die and cools down, it is essential for the integrity of the assembly that a good adhesion was achieved between the layers during this relatively short contact time in the melt state. In the typical food packaging application, a polar central layer acts as a barrier to oxygen and water, while the two outside layers (typically a polyolefin) impart their ductility to the assembly. Two additional tie-layers are necessary to obtain a good adhesion between the polar layer and the polyolefin. th tie-layer contains typically some modified polyolefin chains which are miscible with the polyolefin layer and can react chemically with a polar function on the center layer

In coextruded polymer multilayers, several polymers are put in contact in the melt state in a specially designed die within the extruder. Once the multilayer has exited the die and cools down, it is essential for the integrity of the assembly that a good adhesion was achieved between the layers during this relatively short contact time in the melt state. In the typical food packaging application, a polar central layer acts as a barrier to oxygen and water, while the two outside layers (typically a polyolefin) impart their ductility to the assembly. Two additional tie-layers are necessary to obtain a good adhesion between the polar layer and the polyolefin. th tie-layer contains typically some modified polyolefin chains which are miscible with the polyolefin layer and can react chemically with a polar function on the center layer

More info :

Laurens, C., Ober,R., Creton, C. and Léger, L. (2004) "Crystalline Orientation and Adhesion at polypropylene/polyamide 6 interfaces compatibilized with syndiotactic polypropylene-polyamide-6 diblock copolymers". Macromolecules, 37, 6806-6813.

Laurens, C., Creton, C., Léger, L. (2004) " Adhesion promotion mechanisms at isotactic polypropylene/polyamide 6 interfaces : role of the copolymer architecture ", Macromolecules, 37, 6814-6822.